Jörg Neuner, Head of Gaggenau’s brand centre in Lipsheim, France

Jörg Neuner, Head of the Gaggenau Brand Centre, speaks to LUX about heritage, handwork, and embracing a hybrid design philosophy

Seamlessly absorbing technological advancements into its DNA, the Gaggenau design philosophy is second to none. The secret? “Traditional handwork with the lightest of mechanical touches,” says Jörg Neuner, Head of the Gaggenau Brand Centre.

LUX travelled to Lipsheim in north-eastern France to speak all things design with Neuner, and find out how – from champagne-supplemented culinary workshops to getting down and dirty in the forging room – the centre offers visitors a fully immersive expression of the Gaggenau brand.

Follow LUX on Instagram: luxthemagazine

LUX: How has the Gaggenau Brand Centre evolved since its opening in 2012?

Jörg Neuner: When we originally opened the Brand Centre, it was based just on design. Our first ambition for the space was for our internal product training, so it was used primarily for prototypes and new products. When there were guests here, like trainers and dealers, it also gave them the chance to visit the factory. That’s the interesting thing, to look behind the scenes and see how it’s all done – the handwork, the materials, and so on. So, that’s what we’ve been doing here since 2012. In 2019, after seven years of operation here, we had 10,000 visitors!

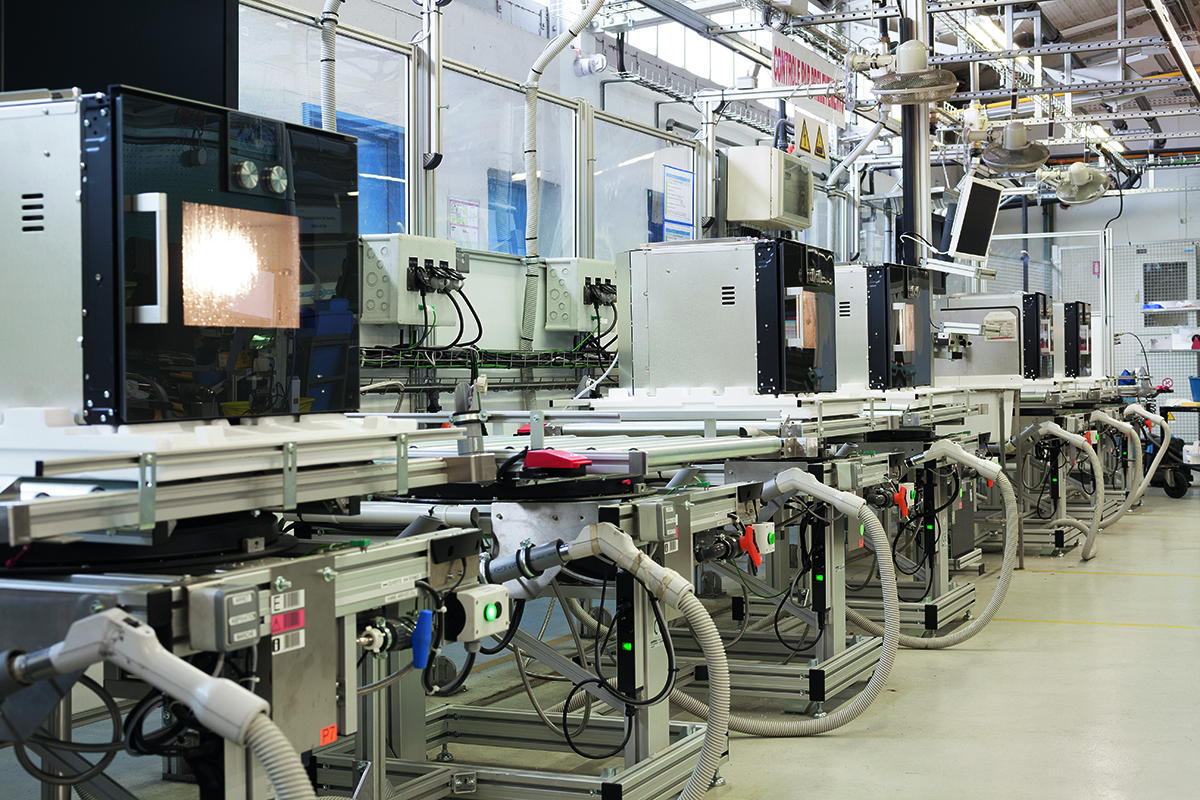

The Gaggenau Brand Centre, featuring a showroom, space for training courses and working kitchen, is located next to the brand’s historic factory

LUX: What makes the Lipsheim location different to other Gaggenau showrooms globally?

Jörg Neuner: We have showrooms like the one here in countries all around the world, and they’re all in the same style. I think what draws people to Lipsheim is the factory, being in the place where everything happens. Normally, we have all the guests here, aprons on, sleeves up, and in the kitchen; you can go and see inside the factory, too. That’s why people come. It’s a very dense experience of the brand, probably the most dense that you can have. Everything we do here is related to Gaggenau: its history, its characteristics, the products.

LUX: What does a typical visitor to the centre look like?

Jörg Neuner: Most of the groups that come here are dealers or retailers. A particularly important group is the product developers, the people building high-rise buildings completely equipped with Gaggenau. They travel throughout Europe to visit all the suppliers they have in their buildings, and they come here to see how it’s done, to understand the brand. Even if they are old-timers with Gaggenau, and have a strong knowledge of the brand, they always say how good it is to come and see how we do it – to see that, still, the products are unique. Now, too, because we have this next to the factory, we can really provide an event.

Visitors to the centre can also tour the factory to gain an insight into how the brand’s products are made

LUX: What does the centre have in store for its private clients?

Jörg Neuner: For the moment, the main thing for end consumers is our cooking classes. We have star chef here, from the region, who has a long-time connection with Gaggenau. He does a cooking course here every month, so you can come here, if you pay a certain fee, to cook lunch with him with a glass of champagne. It’s a big dream of ours, to accommodate more private clients in the future.

LUX: One of the most fascinating elements of the centre is the heritage pieces. Is that something you’re interested in, showing more of the brand’s heritage?

Jörg Neuner: Sure. We have a little interactive forging museum with some of our old appliances in it. I always see guests with big smiles on their faces when they take the hammer and make a piece of really authentic heritage using their own hands, which they get to take home with them. This is how we communicate our history: we try to put guests in touch with it, to make it as tangible as possible.

Read more: Vitalie Taittinger on family business and philanthropy

LUX: Which aspect of the manufacturing process is most surprising to visitors?

Jörg Neuner: I think the most fascinating thing is that with every process, there are people involved. There is still so much handwork and complexity involved, which we try to show to visitors. We have only one process that is automatised, which cuts flat sheet metal and can run around the clock, but in all other processes we have people. It’s really traditional handwork too: we don’t cut any corners. The best example is the 90cm oven. The door takes ninety minutes to assemble, and it’s one person, putting together 515 pieces, 37 metres of cable, step by step, all alone. 90 centimetres, 90 minutes: one centimetre a minute. It’s quite a huge depth of production. That’s really special, and it’s important for the dealers when they come to see it here.

Traditional craftsmanship is at the heart of Gaggeanu’s manufacturing processes

LUX: Technology has not replaced the human element of Gaggenau’s manufacturing process, but has it influenced the design evolution of products over the years?

Jörg Neuner: Our philosophy for our products is traditional avant-garde. We respect where we have come from – how people have cooked, what they know, what traditions there are – and, when it makes sense, we incorporate technology. For example, all the tapping indicators on the induction and ceramic cooktops have knobs. We have some [appliances with] touchscreens as well, for flexibility, so that you can do further programming, but you have full control at the manual level. Modular products have also come up over the course of the last few decades. With Gaggenau it started by developing our ovens, making the panels smaller, giving the cavity more space; and eventually we put the oven not below the cooktop but into the wall. We were the first ones to do that. Then, we realised, with this new development, that you could combine it with the steamer, or the coffee machine, and that brought up new forms again. It all contributes to a certain story about the ergonomics of cooking; it’s not just an oven without a panel. So that shows how, on the one side, things develop, and we get a new avant-garde style, but on the other side it still has the things which still make sense. That’s the traditional avant-garde.

LUX: Have any Gaggenau designs remained untouched by time or technology?

Jörg Neuner: We now have two oven series, the 200 and the 400, while the 300 stays as an icon. We did our first attempt to update that one, and I was very happy, and it’s stayed the same ever since. To me, that’s amazing: that you can have an appliance for thirty years in the catalogue without any major change in the design or technology. Nobody else has that. We have a successor, but while it’s technically based on our new oven platform, with the same functions and features, the outline is the same. It has the same face. For me, that’s the Gaggenau face.

Find out more: gaggenau.com