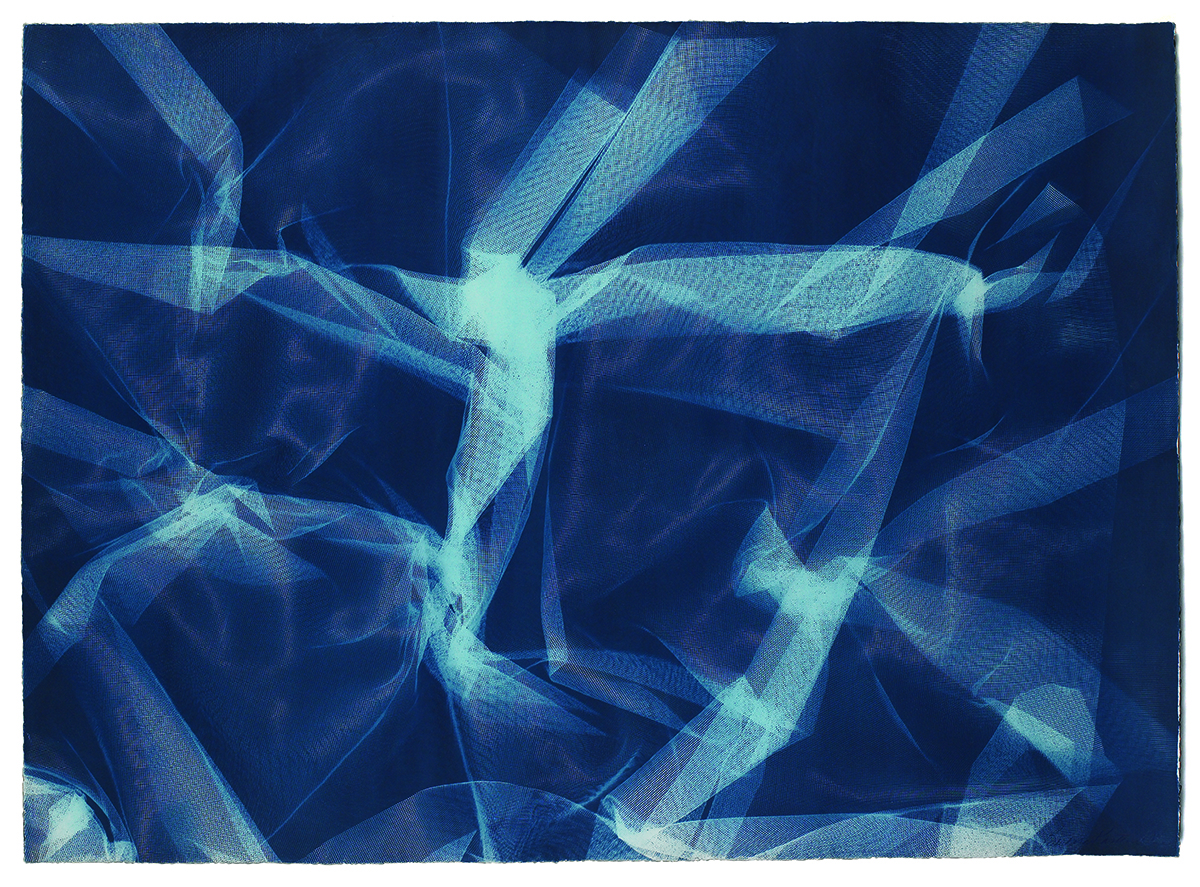

Photogenic Painting, Untitled 75/31, Barbara Kasten. Copyright & courtesy the artist

Barbara Kasten is one of the most intriguing and influential photographic artists of the past 50 years. Born in the US before the second world war and initially influenced by the Bauhaus movement of the 1930s, her work seems to meld two dimensions into three and defy easy categorisation. In a rare interview, she speaks to Millie Walton about some of her techniques ahead of her postponed solo show at Kunstmuseum Wolfsburg in Germany

“I do not think of my work as abstract photography. My abstraction is a search for a fleeting moment in time when a nondescript, real thing is transformed and perceived in another state of being. By definition a photograph records reality. I use photography to capture a unique abstraction of perception which can only happen with the interaction of light. It’s about how materials interact with light and how light is so essential to the way that we look at the world.

Follow LUX on Instagram: luxthemagazine

“Normally, my interest is in the material that I’m using and its properties so there’s a lot of controlling and experimentation, and that’s the initiating point for me. I make shapes out of these materials that have no representational value; they are basic geometric shapes, building blocks, which is where the relationship to architecture comes in. Everything that I build in front of the camera is not held together, it’s balanced on each other. I’m building something that looks like an object, but I don’t want it to look like an object so I cancel it with what happens when the light hits and the shadows create other objects that are fleeting. The shadows also become building blocks, but they’re not there so it creates this contrast between the real and the unreal.

Architectural Site 19, July 19, 1989, Barbara Kasten. Copyright & courtesy the artist

Architectural Site 17, August 29, 1988, Barbara Kasten. Copyright & courtesy the artist

Architectural Site 15, Whitney, 1989, installation shot with the artist. Copyright and courtesy the artist

Read more: In the studio with the radical New-York based artist Mickalene Thomas

“All of my work is in the studio so I can move the light to achieve a different perspective of the object, but I don’t move the camera. I build in front of it and because [the viewer] is large, I can look at it as I might look at a painting where if a shape is not in a compositional relationship to another shape that I like then I can go in and change it by moving the object or the light. In that way, it’s a very painterly organisation and composition that I create, but then there’s also the three-dimensionality of the sculpture that is a different experience to the three-dimensionality as it is translated to the flat surface. I think that’s one of the reasons why more recently I’ve been taking what I call the set-ups in front of the camera and treating them more like standalone sculptures. I don’t make a photograph, I just use the same kind of material elements and I allow the audience to see what I see before I go to the back of the camera because once I’m looking through the camera, it’s my point of view and it’s frozen in the moment. Now, I’m more interested in how I can broaden this experience so that other people see the discovery for themselves.”

Crown Hall, Artist City, 2018, Barbara Kasten. Copyright and courtesy the artist

Due to Covid-19, the artist’s solo exhibition ‘Works: Barbara Kasten’ at Kunstmuseum Wolfsburg has been postponed, and is expected to open later this year. For updates, visit: kunstmuseum-wolfsburg.de

View the artist’s full portfolio of work: barbarakasten.net

This article will also be published in the Summer 2020 Issue, hitting newsstands in May 2020.

Recent Comments