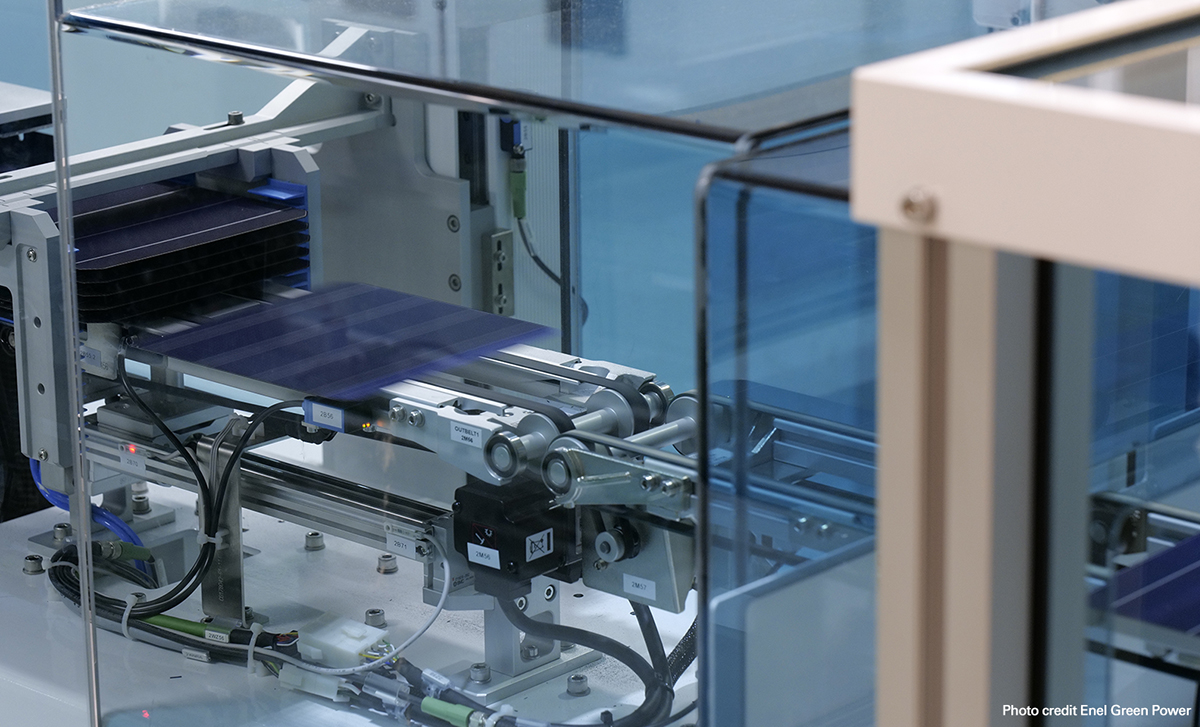

3Sun Gigafactory opened in 2011

Eliano Russo is Head of Enel Green Power’s 3Sun Gigafactory in Catania. Here he speaks to Samantha Welsh about the way the factory works, its benefits on the local community and the clean energy transition

Eliano Russo

LUX: What is a photovoltaic cell and how does it work?

Eliano Russo: Solar cells are the heart of solar power generation systems. A photovoltaic cell is a device that can convert the energy of solar radiation into electricity through the photovoltaic (PV) effect. This effect is possible since photovoltaic cells are usually made of semiconductor materials (the most diffused is silicon), which have weakly bonded electrons. When the light of the sun hits the PV cell, the electrons of the semiconductor receive energy from the light’s photons and are then able to move. The movement of these electrons through the metallic contacts of the cell produces an electric current. PV cells are assembled into photovoltaic panels that find applications in several fields.

LUX: What are the peculiarities and advantages of the technology 3Sun offers?

ER: 3Sun offers cutting-edge technologies in solar cell and PV module (or panel) manufacturing. Our solar cells are based on bifacial silicon heterojunction (HJT) technology, which offers several advantages over the most widespread technologies on the market. Moreover, our PV modules are manufactured in Europe with sustainable materials derived from a regulated supply chain.

3Sun Gigafactory combines research and innovation to produce new-generation photovoltaic modules that support the Enel Group in guaranteeing clean and renewable energy

Continuous innovation in pursuit of the highest level of cell efficiency is a fundamental value as we strive to maximise the effective transformation of the sunlight that hits our panels into energy. HJT technology is characterised by high performing photovoltaic modules with low degradation and in early 2020 our HJT cell achieved a world record efficiency level of 24.63%.

The double-sided structure of the solar cell allows solar radiation to be captured via direct light on the upper surface, as well as reflected or diffused light on the lower side. “Bifaciality” also guarantees extra power output even with cloudy conditions where the amount of diffused light is quite high. The solar cell is also very resilient to thermomechanical stresses thanks to the temperature during the manufacturing process that does not exceed 200°C, which also allows for thinner solar cells to be manufactured, , thus reducing the use of silicon and cutting costs.

LUX: What are the benefits for the solar supply chain and the European energy sector in general?

ER: For Europe, the photovoltaic sector represents one of the main enabling technologies to accelerate a sustainable and competitive energy transition. To reach its decarbonisation goals, in Europe we need to achieve 600 GW of installed solar capacity by 2030, which requires building and installing an additional 440 GW. On the other hand, in order to increase the continent’s energy independence and reduce risks related to external geopolitical factors, it is important not to become overly dependent on supplies from other geographies.

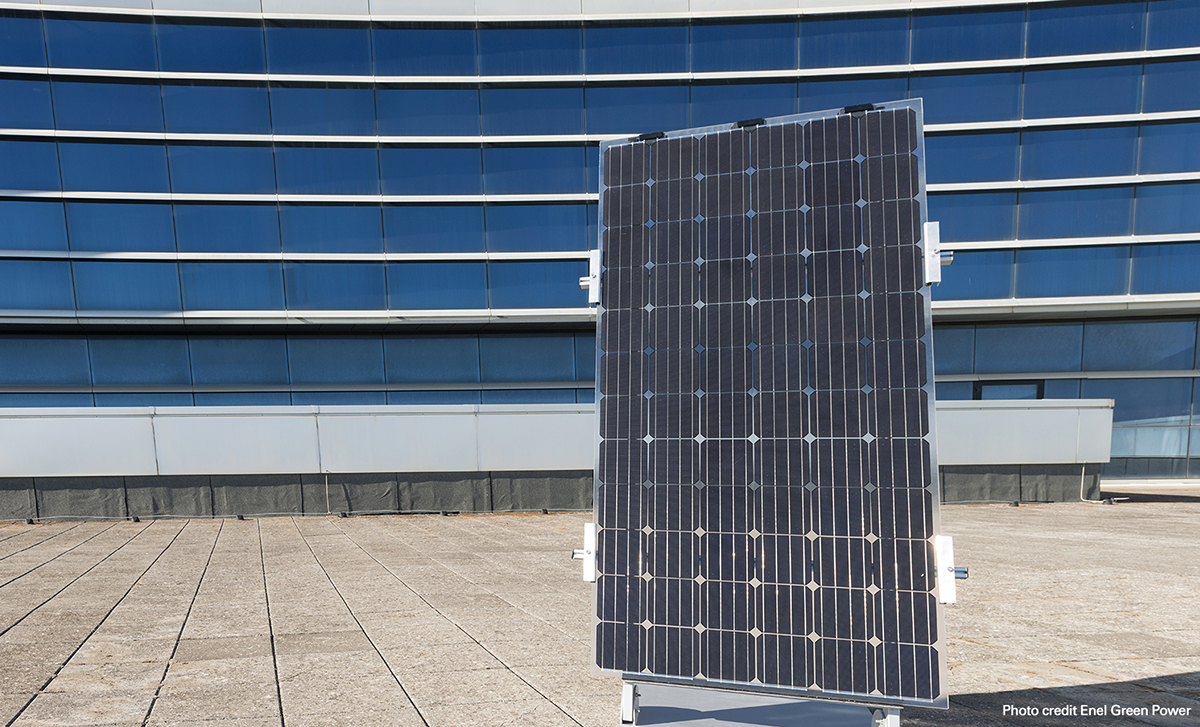

Italy’s HJT Photovoltaic Panel

Today, a large part of the photovoltaic industry supply chain is still concentrated in the Asian market, especially in China, where there is also less emphasis on environmental, energy and labor standards compared to those in Europe. Therefore, the creation of a European photovoltaic industry that can guarantee our energy security and independence while upholding those standards represents a strategic priority. In order to achieve this, we must invest to reshore the solar PV supply chain in Europe as we did in Catania, Sicily with the construction of what will be the largest solar gigafactory on the continent.

LUX: What is the potential impact for local communities?

ER: One of the most important positive impacts for the local community as a result of the factory’s expansion is the employment opportunities for Sicily, increasing local direct and indirect employment. In 2022, 50 university graduates were employed, while the selection process for an additional 100 is currently underway, as well as the selection for hiring 550 secondary school graduates. With the new hires, who will fill technical and operational positions in areas such as production, maintenance, auxiliary services, product quality and plant operation, 3Sun’s team, which already includes more than 200 people, will reach about 900 people in total. In addition, 3Sun will also generate a total of 1,000 indirect jobs, including current ones, by 2024. . These numbers mean a lot in terms of employment for a territory like Sicily, especially for young people. In some cases this means young people who have had the opportunity to return home after years of working abroad, excited to be able to contribute to the realization of a project as important as this one.

Bifacial solar panel production at the 3SUN Factory

LUX: How essential is political collaboration to clean energy transition?

ER: It simply cannot be done without it. Our current climate policies are the direct consequence of a political commitment that we took together as Europeans and, more widely, as countries committed under the Paris Agreement. The challenge of climate change is global, it affects everyone, and the response can only be global. A strong, collective, political commitment is needed to tackle a problem of this magnitude. But the political commitment must also be matched in the private sector along with the actions of each and every one of us as individuals.

LUX: What is the role for regional partnerships in tech innovation?

ER: We will be the largest European PV factory, basing our manufacturing on the most advanced technology processes, materials, and design. We carried out a robust research and development phase in collaboration with the most important research institutes and development companies in Italy, Europe and the US. In fact, 3Sun has triggered the most advanced research consortium in Europe with renowned partners such as CEA-INES in Chambery (France), Italian Institutes such as IIT, CNR, ENEA, as well as European and Italian universities. The strict collaboration with the research centers is also witnessed by the presence of very advanced research labs within the industrial complex of 3Sun and in the nearby Enel Innovation Hub and Lab, which hosts research institutions and start-ups. The concentration of research institutes and industries in a few kilometers also encourages important exchanges and generates a very fruitful environment for the development of innovative ideas not only in the PV field. Beyond research collaborations we also work with a wide range of subcontractors in the supply chain of strategic and innovative materials as well as of advanced industrial support and maintenance processes.

The first HJT cells were produced in February 2019 and mass production began in August 2019

LUX: Please share the aims of Project TANGO

ER: TANGO is the acronym for iTaliAN pv Giga factOry, the name of the project through which we are creating an industrial-scale production facility for the manufacturing of innovative, sustainable and high-performance PV modules at Enel Green Power’s 3Sun solar panel factory in Catania. In April 2022, under the framework of the European Commission’s (EC) first Innovation Fund call for large-scale projects, EGP and the EU signed a grant agreement that contributed to the development of TANGO, a facility that will have a production capacity of 3 GW per year by mid-2024. Of our total investment of around 600 million euros, the EC has contributed up to 118 million euros and around 70 million euros came from the Italian National Resilience and Recovery Plan.

LUX: How is the 3Sun Gigafactory in Catania innovating to leading the transition to green energy?

ER: Our production capacity of 3 GW, which we will reach in 2024, will make us the largest production facility in the photovoltaic industry in Europe. However, our contribution to the energy transition is not only quantitative but also qualitative. The values that guide us are innovation and sustainability, two pillars that enable us to create a high quality product made in Europe.

3Sun Gigafactory represents a model that could be used all over the globe

LUX: Can you accelerate performance to be sure of meeting targets?

ER: We won’t ever stop innovating. The architecture of the 3Sun HJT solar cell is highly compatible with the so-called Tandem structure in which a perovskite top cell is coupled with a silicon bottom cell, the top cell utilises the blue component of the solar spectrum and transmits the red component to the silicon solar cells. The 3Sun tandem structure, that we call “Tango Technology”, allows the solar cell to reach higher efficiencies, well above the theoretical limits of silicon solar cells. 3Sun is developing innovative technology with the aim of increasing solar cell efficiency, achieving more than 30%.

LUX: Longer term, how do you see 3Sun Gigafactory model developing?

ER: 3Sun Gigafactory represents a model that could be replicated elsewhere in Italy, Europe and other parts of the world. As outlined previously, in order to accelerate the energy transition and ensure energy independence and security in Europe, it is necessary to build a European ecosystem of highly efficient solar PV module manufacturing.

Find out more: enelgreenpower.com/3SUN-factory